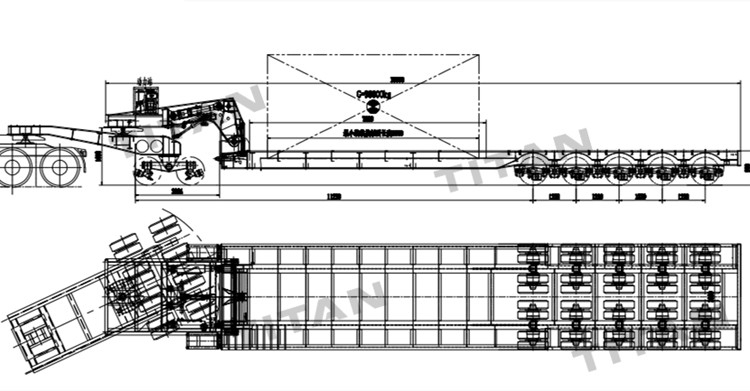

Drawing of 5 Line 10 Axle Detach Gooseneck Lowboy Trailer for Sale

Dimension: 18450mmx3400mmx2250mm

Loading capacity(T): 200 ton

Axle: 5 line 10 axle, TITAN Brand

Tire: 40 units, 12R22.5

Suspension: Mechanical suspension

Spring leaf: 120(W)mmx16(Thickness)mmx10 layers

Kingpin: JOST brand 2.0 or 3.5inch(bolted or welded type)

Main beam: Height: 500mm; Width: 230mm; Side beam: 250 I-beam 10/8/10; Material: HG60 high-strength steel.

Bottom Platform: 5mm thick, checkered plate

Hydraulic cylinder: 12KW diesel engine with hydraulic station

ABS: Optional

Valve: WABCO valve

Light: LED light (specially intended for oversea markets)

Voltage: 24V

Tool box: 1 set

Painting: Polyurethane paint, with long service lift, and avoid the vehicle get rust

Drawing of 5 Line 10 Axle Detach Gooseneck Lowboy Trailer for Sale

Drawing of 5 Line 10 Axle Detach Gooseneck Lowboy Trailer for Sale

Uncoupling for Loading

During coupling and uncoupling, the trailer assembly is let to a lowered position. During uncoupling, the safety pin handle gets puled and locked open to let the safety pin detach the T-bar yoke free from the yoke pocket. The control lever for the hydraulic ram feature on the other hand is maneuvered to provide hydraulic pressure fluid inside the dram in order to lift the thrust blocks somewhat clear off their sitting positions on the main beam.

After achieving this, the lock finger gets retracted and the crank handle then is swung in an upward manner to anchor the safety hooks and the thrust blocks upwardly. Once this is attained, the lever is then locked in position through the lock finger that is fit in an upper coupling hole for the same.

Next, the hydraulic ram feature gets extended further to facilitate a further gooseneck rotation with respect to the trailer bed. This is done to facilitate the withdrawing of the two lock pins that are engaged with the hooks.

The pins get swung in an upward manner through the use of the crank handle. On achieving this, the hydraulic pressure in the ram gets reversed hence allowing the pressure to go down in the cylinders’ bottom chamber. This action slowly lowers the gooseneck and the trailer bed to the ground. You can choose to place a removable support block in between the trailer frame and the gooseneck beam in order to keep the gooseneck slightly off the ground surface. It is at this point when you can move the tractor away in order to give room for loading.

Coupling for Transportation

Once your cargo has been safely loaded on the lowboy trailer bed, it is time to reconnect the gooseneck and the trailer bed ready for transit. Basically, this is a reverse procedure of the uncoupling operation.

First, the operator needs to reverse back to the trailer bed location. Ensure that the coupling hooks are set in position to facilitate easy engagement.

The forward section of the trailer bed has a forwardly swerving entryway to make the hooks align with their attaching positions. When the T-bar yoke is perfectly aligned with the yoke pocket, fluid pressure can now be supplied to the hydraulic cylinders’ top chambers.

This forces the piston rods downwards hence driving the T-bar yoke directly into the pocket. The safety pin is then inserted to ensure a positive link between the pocket and the T-bar yoke. More hydraulic pressure is supplied into the cylinders to move the trailer bed and the gooseneck in an upward direction.

The trailer bed should be moved to reach a position higher than its horizontal operating level to facilitate the moving of the lock pins into their perfect locking position. Once this is achieved, the hydraulic rams are then retracted back to allow the trailer bed and the gooseneck to descend.

The next thing is to move the safety hooks and the thrust blocks downward into an engaging position to lock them in place. After that, the fluid pressure in the rams is then reversed moderately. This provides a hydraulic interlock that holds the thrust blocks tightly in place. Once this is done, the lowboy trailers for sale near me assembly is now ready for over the road transportation.